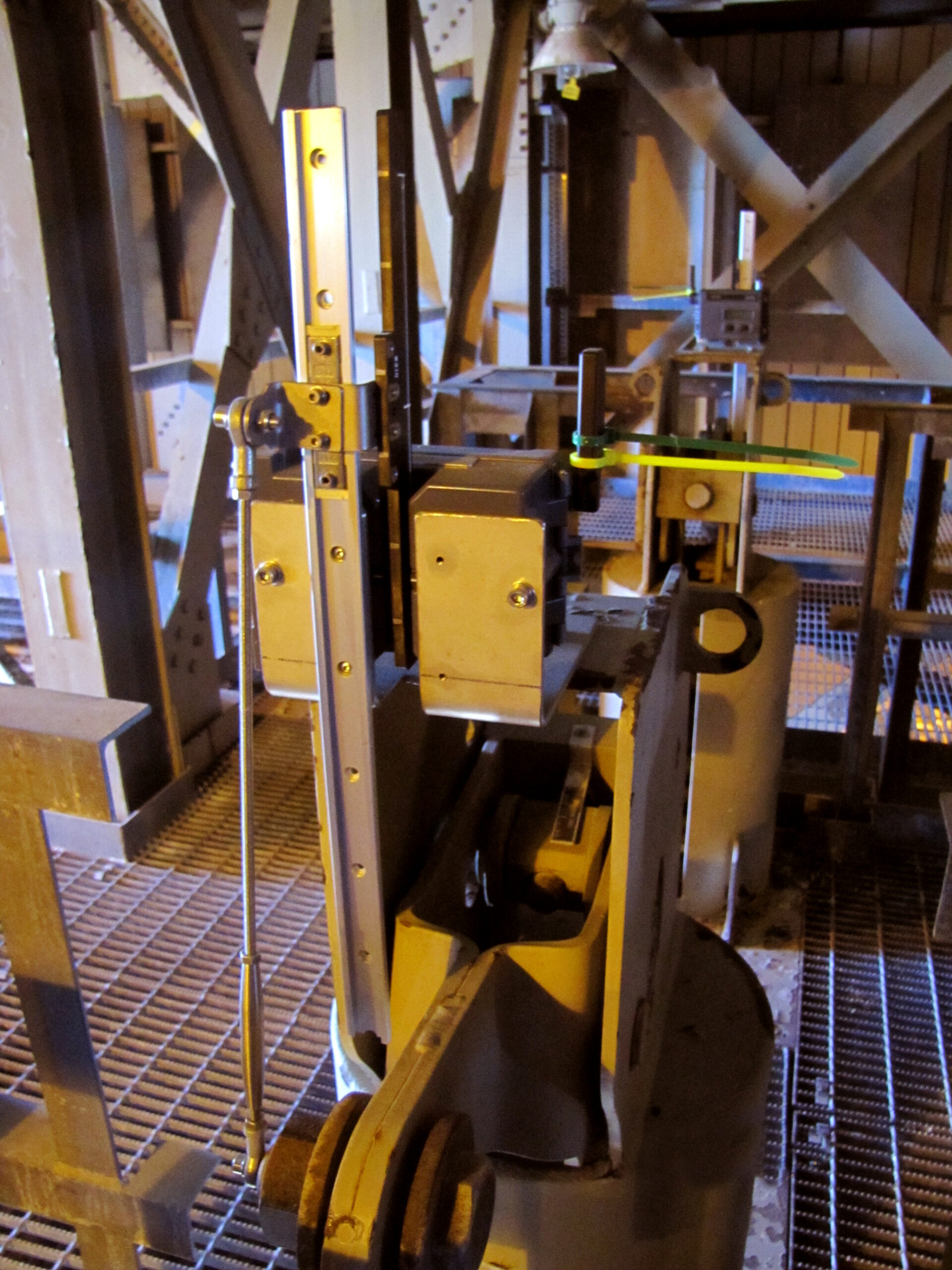

The Tube Growth Monitor, or TGM, is a real-time monitoring system that helps operators protect their reformers from overheating and tube failures. By measuring the thermal expansion of reformer tubes, TGM can detect changes in temperature earlier than current instrumentation, allowing for preventative measures to be taken. TGM also helps support accurate tube life estimation, which can help operators plan maintenance activities and avoid costly unplanned outages.

Here are some of the benefits of using TGM:

• Reduced risk of overheating and tube failures: TGM's real-time monitoring can detect and prevent overheating incidents that can cause costly tube failures.

• Improved reliability: By identifying potential problems early, TGM can help operators avoid unplanned outages, which can disrupt production and cost money.

• Improved operating temperature uniformity: Real-time accurate mapping of tube temperatures allows operators to adjust reformer firing to improve temperature distribution, extending catalyst tube life.

• Tracking of tube life consumption: TGM's accurate tube temperature measurement can help operators plan maintenance activities more effectively, which can save money and reduce downtime.

TGM can have a significant impact on the daily work of an operator on a plant. By providing real-time monitoring of the reformer, TGM can help operators identify and address potential problems before they cause costly outages. This can free up operators to focus on other tasks, such as optimizing production and improving efficiency.

TGM can be a valuable tool for operators on a plant to:

• Improve reliability: By identifying potential problems early, TGM can help you avoid unplanned outages, which can disrupt production and cost money. This can help to keep your plant running smoothly and efficiently.

• Save money: TGM can help you save money on maintenance costs by supporting accurate tube life estimation. This can help you plan maintenance activities more effectively and avoid costly unplanned outages.

• Improve compliance: TGM can help you comply with safety regulations by providing real-time monitoring of your reformer. This can help you to avoid costly fines and penalties.

• Reduced risk of costly tube failures: TGM's real-time monitoring can detect and prevent overheating incidents, which can cause costly tube failures. This can save the plant money on maintenance costs and lost production.

• Improved plant reliability: By identifying potential problems early, TGM can help the plant avoid unplanned outages, which can disrupt production and cost money.

• Optimized maintenance schedules: Accurate tube life estimation, with TGM’s contribution, can help the plant plan maintenance activities more effectively, which can save money and reduce downtime.

• Improved compliance: TGM can help the plant comply with safety regulations by providing real-time monitoring of the reformer. This can help the plant to avoid costly fines and penalties.

Overall, TGM is a valuable tool that can help the plant improve its safety, reliability, and efficiency. This can lead to reduced costs and increased profits.

When looking at TGM as an investment, the cost is always important, and the benefits of TGM speak for themselves:

• The cost of TGM: The cost of TGM will vary depending on the size and complexity of the plant. However, in general, the cost of TGM is a small investment compared to the potential savings that it can provide.

• The payback period: The payback period for TGM will vary depending on the specific needs of the plant. However, the payback period for TGM is typically less than two years.

TGM CAN HELP PLANTS IMPROVE THEIR SAFETY , RELIABILITY , AND EFFICIENCY